Services and support

We are committed to delivering the highest possible value for your vessel and business.

We offer a full framework of services, helping you to get the most out of our lubrication systems.

Our service philosophy is based on three pillars; customer satisfaction, adding value and deep technical expertise.

We support you and your team in realizing the full potential of your lubrication system, all the way from identifying the right solution to servicing and monitoring performance in the following years. We are with you all the way.

Every day we measure our performance based on customer feedback because we value long-term relationships with our customers. We go a long way to match your need for services and support – both in port and at sea.

For enquiries (Asia and Europe)

Phone:

+45 98 57 19 11

NEW: Service option

Cylinder Liner Wear Measurement – VAK

With modern two-stroke marine engines optimized for high efficiency, they are increasingly complex to operate and maintain. At the same time, legislation demands lower emissions and pushes the use of new fuels, cylinder sensitivity increases and the risk of cylinder problems.

Hans Jensen Lubricators is a global leader in cylinder lubrication technology with expert knowledge of cylinder condition gathered over more than 100 years.

Using a Cylinder Gauge Insertable (CGI), we offer an accurate measurement of cylinder wear that shows the actual cylinder condition.

The VAK measuring process is time efficient. It takes one person approx. 1½ hour of work per unit because removal of cylinder cover is unnecessary, so cylinder condition can be determined quickly with minimal disruption.

In addition, using a Ninja DS-cam provides clear and reliable pictures of the entire combustion space with 3D images.

Benefits:

- Determines true cylinder liner condition

- Detects abnormal wear early on

- Identifies type of cylinder wear

- A safe, time-efficient and accurate measurement method

- No need for lifting cover or exhaust valves

- Only one person required for the task

- Suitable for most two-stroke engines

When to measure:

- Suspicion of abnormal cylinder wear

- Periodical slow steaming

- Retrofitting for green fuels

- Changing bunker supplier

- Inspection prior to dry dock

- Monitoring wear during new engine run-in

Service option

Cylinder condition evaluation – CCOP

Optimize cylinder conditions and realize the full savings potential of your HJL solution.

Increased complexity

Avoiding engine problems is becoming increasingly complex. Among the challenges are new environmental regulations (SECA, IMO2020, EEXI, CII etc.), design changes of two-stroke marine engines (higher temperature, higher combustion pressure, increased stroke length in the X- and G-type engines) and new operation requirements (such as slow steaming/part load operation).

During the last 100 years, we have gained experience and knowledge from optimizing the cylinder condition and feed rate onboard different engines operating under different operation requirements.

That’s why it’s more important than ever to work with cylinder lubrication specialists to help maintain a healthy cylinder condition.

Not just another SDA

We conduct a root cause analysis along with continuous optimizations so that you can avoid problems before they occur. We take all your actual parameters into consideration, such as your lubrication system, engine design, piston ring design, fuel and cylinder oil in use.

Based on these insights, our specialists compile a report with specific recommendations on the correct feed rate setting, improving cylinder condition, the time between overhauls, reducing cylinder oil consumption and detecting early warning signs (eg. cold corrosion).

Advantages:

- Improved engine performance and condition

- Improved cylinder condition

- Extended Time Between Overhaul (TBO)

- Detection of early warning signs (eg. cold corrosion and build-up deposits on piston rings)

We recommend a quarterly evaluation of your cylinder lubricator solution.

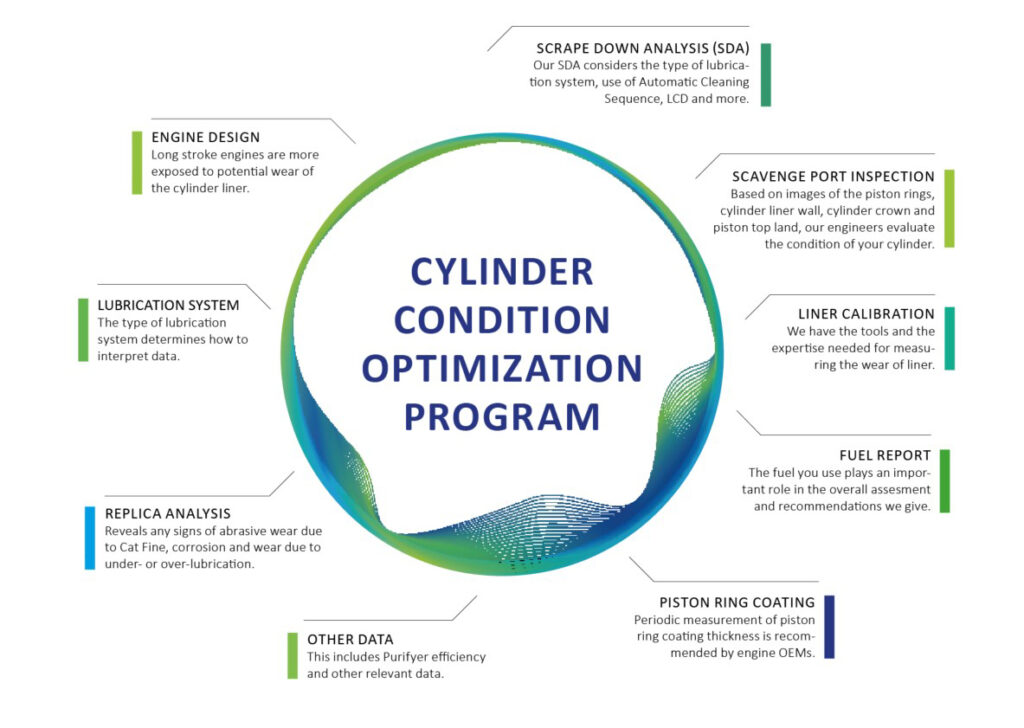

CCOP program elements

Service option

Lubricator overhaul

Our lubricators are made according to the highest quality standards, but just like any other equipment they sometimes need servicing.

We offer an overhaul of our lubrication systems at regular service intervals, which can be done either on an exchange basis or by onboard attendance from our experienced service engineers.

– Please contact us for more information.

Service option

SIP valve overhaul

To ensure maximum performance of your HJL SIP valves, an overhaul is necessary at regular intervals.

We recommend 12-15,000-hour intervals or approximately 2 years of operation between service. This prevents unplanned, costly downtime and ensures maximum value of your Hans Jensen Lubricators investment.

– Please contact us for more information.

HJ Academy

As technology evolves and engine crew face a wider range of tasks with less time for specialization, we offer our clients the training they need. Whether you want to receive your training online, have our engineers come aboard your vessel, or set up a seminar in another physical location, it’s up to you. Our engineers are experts in cylinder condition and lubrication technology so we are able to tailor the training process to fit your exact needs.

Let’s talk about your training needs.

Let’s talk

Request more information about our services here or order service/support for your vessel.

If you are a customer, please include your IMO and vessel name along with other relevant information in the text field.