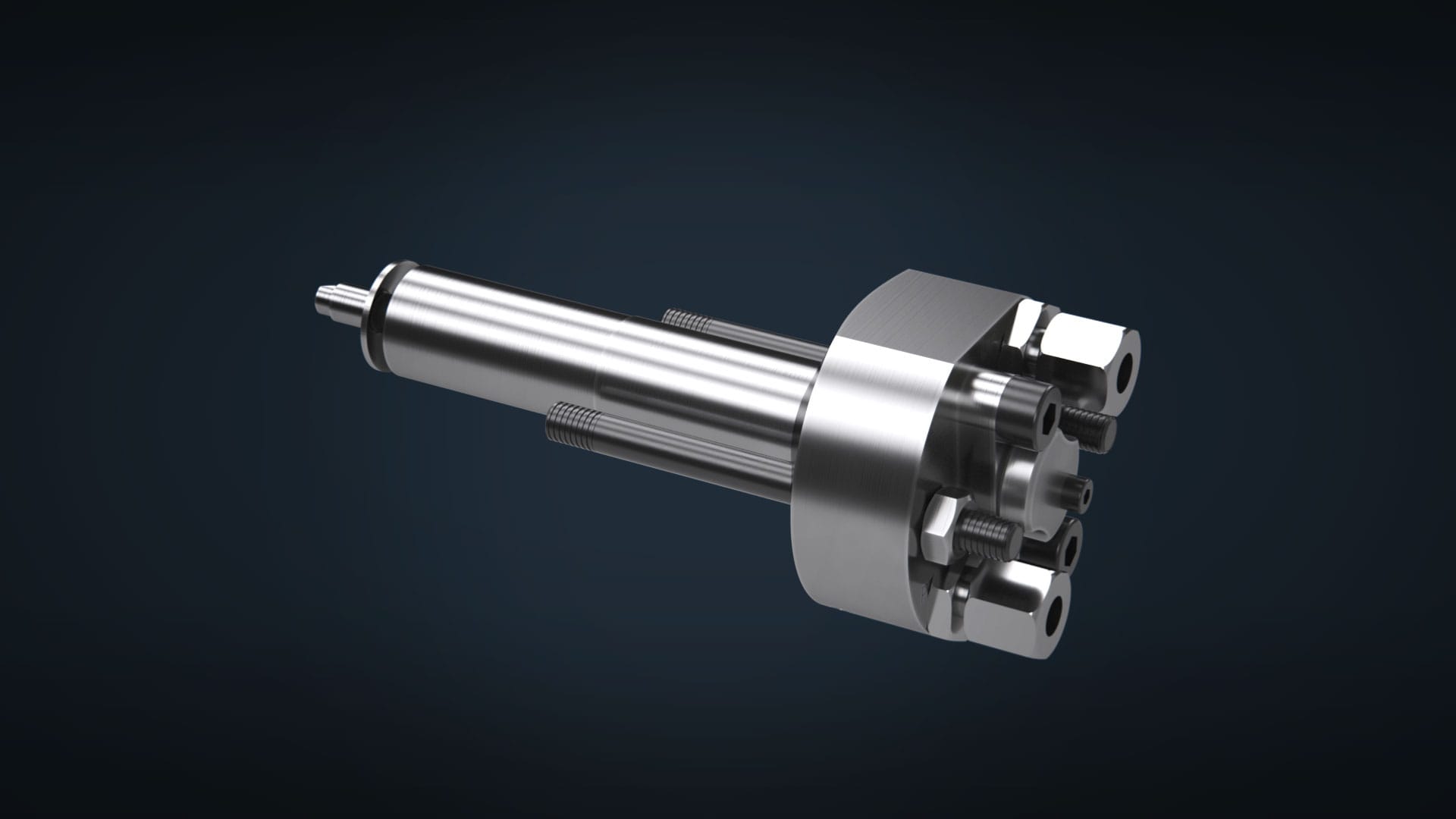

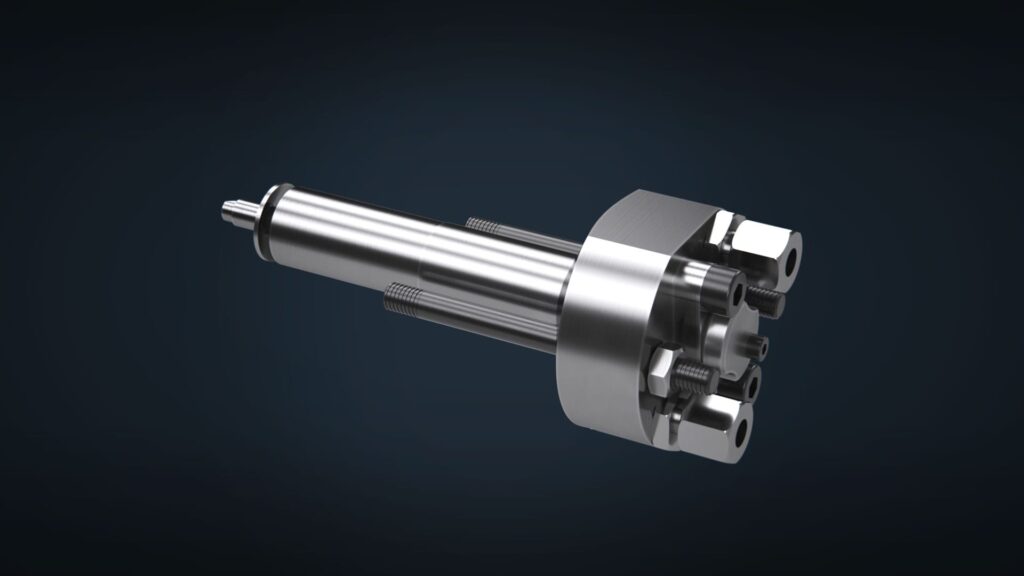

HJ SIP valves

Patented technology atomizes the spray of lubrication oil for optimal distribution on the cylinder liner wall, utilizing our Swirl Injection Principle.

HJ SIP valves compared to conventional NRVs

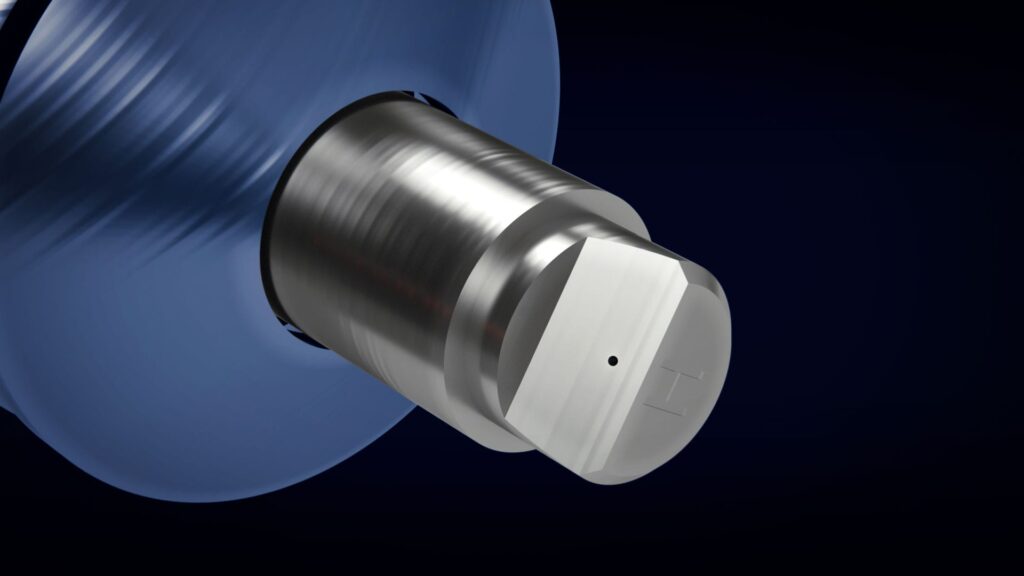

Swirl Injection Principle

Our ‘Swirl Injection Principle’ utilizes engine scavenge air to distribute the cylinder-lubricating oil. For each piston stroke the engine takes, a small amount of cylinder-lubricating oil is sprayed from the HJ SIP valves.

The system prevents wear and corrosion of the liner by atomizing the cylinder lube oil into the combustion chamber. The result is an optimal distribution of the oil on the upper liner surface which is the most vulnerable part of the cylinder.

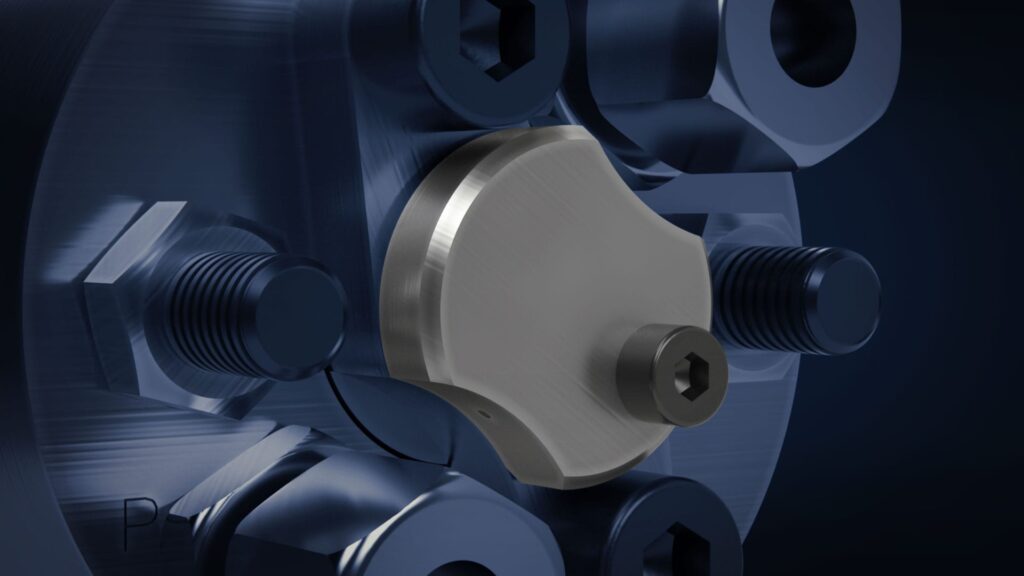

SIP valves on original lubrication systems

HJ SIP valves can be used in combination with other lubrication systems. The SIP valves are mounted onto the liner using the same bores as your existing non-return valves.

BENEFITS

- Up to 50% reduction of lube oil consumption

- Reduced emission of particle matter and CO2

- Improved acid neutralization and reduced corrosive wear

- Reduced wear of liners and rings

- Extended TBO

- Prepared for dual-fuel

- Easy operation for crew

PRODUCT FEATURES

- Oil injection in every piston stroke

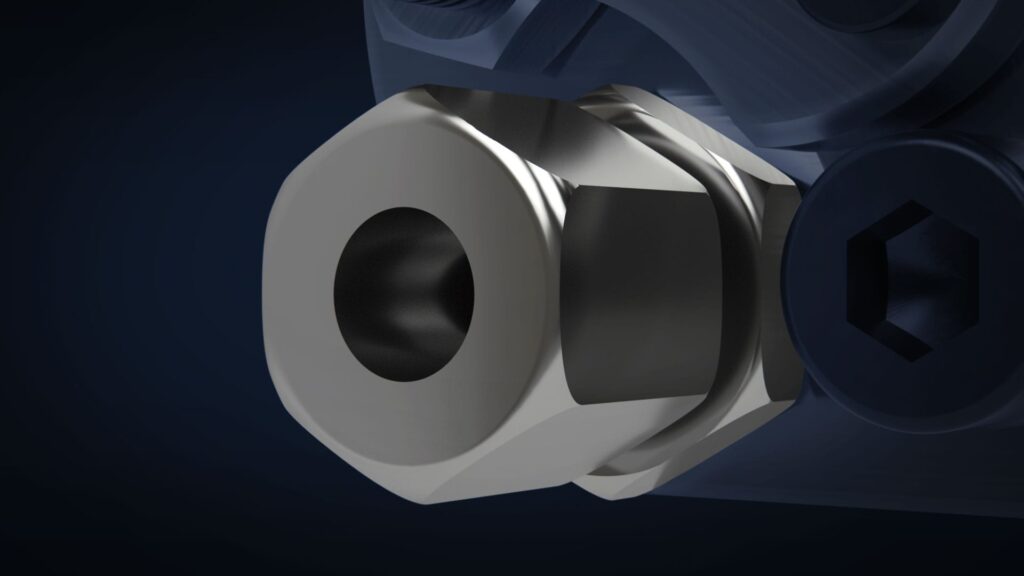

- Atomizing cylinder oil into the combustion chamber

- Automatic load or Sulphur dependent feed rate regulation

- Automatic Cleaning Sequence algorithm (Patented technology)

- Delta-Timing algorithm ensures lubrication into the ring pack and liner

- Sulphur-, load- and BN-dependent algorithms

- Possibility for online monitoring and preventive alarms

Video showing actual SIP valve spray in cylinder

Get the flyer on HJ SIP valves for later reading

CLIENT CASE STUDY: AET

Reducing feed rate by 32%

The marine vessel Eagle Varna was experiencing a high feed rate of the cylinder lube oil. Hans Jensen installed HJ SIP valves on MAN Alpha, which resulted in a significant reduction in cylinder lube oil consumption.

FAQ: HJ SIP valve

SIP stands for Swirl Injection Principle, which is the principle of atomizing cylinder oil and injecting it into the scavenge air swirl at high pressure. The result is an optimal distribution of the cylinder oil on the entire upper liner surface (combustion area) which is the most exposed area in the engine. The technology is patent protected by HJL.

Yes, it is possible to retrofit existing 2-stroke engines of any size with SIP valves.

Yes, in most cases the existing quills are used with only minor processing needed.

We recommend maintenance in regular intervals to ensure optimum performance in the long term. Our service technicians are here to help if you would like to know more.

Let’s Talk

Interested in learning more about HJ SIP valves and lowering lube oil consumption onboard your vessel?

We offer a specific and detailed calculation of ROI – free of charge.