Products

Hans Jensen Lubricators is an independent supplier of lubrication technology for large 2-stroke marine engines.

As an OEM we control our own manufacture of pumps, valves and the equipment needed for our solutions.

PATENTED TECHNOLOGY

Cylinder oil injection in every piston stroke

A unique feature of Hans Jensen Lubricators is the ability to inject fresh cylinder lube oil during each piston stroke to reduce engine wear and corrosion. The dosage of oil is adjusted for optimal effect.

Experience up to 60% less lube oil consumption with Hans Jensen lubrication technology compared to standard lubricators.

PATENTED TECHNOLOGY

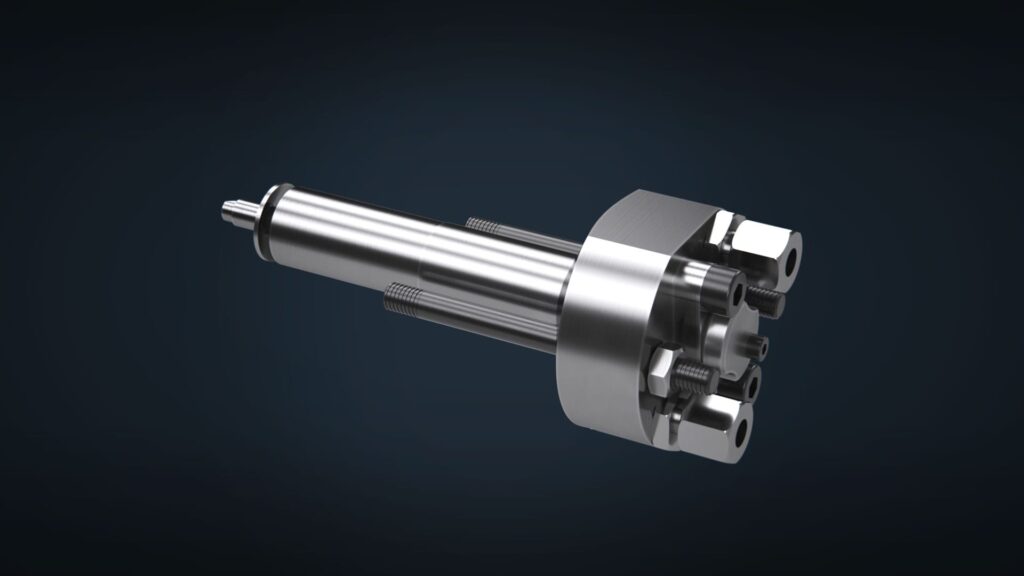

Atomizing cylinder oil into the combustion chamber

HJ SIP valves (Swirl Injection Principle) is the principle of atomizing cylinder oil and injecting it into the scavenge air swirl at a high pressure. The result is an optimal distribution of the cylinder oil on the entire upper liner surface (combustion area) which is the most exposed area in the engine.

Hans Jensen lubricators

More than 100 years of experience in cylinder lubrication technology positions HJL as the leading brand for improving cylinder condition. HJL lubricators provide variable injections of oil during each piston stroke, with our Delta-Timing algorithm and Automatic Cleaning Sequence.

We say: No more dry strokes!

Hans Jensen SIP-valves

Our unique SIP-valves atomize the spray of cylinder lubrication oil into the combustion chamber using our patented Swirl Injection Principle. The engine scavenge air is utilized for efficient distribution inside the cylinder.

For each piston stroke the engine takes, a small amount of cylinder lubricating oil is sprayed out of the HJ SIP valves. Enjoy the benefits of optimal distribution on the cylinder liner, a more stable oil film and lower CLOC of up to 60%.

Hans Jensen Services

HJL offers a range of services to improve cylinder condition and efficiency.

Our Cylinder Condition Optimization Program improves engine performance by setting an optimal feed rate, extending TBO, reducing consumption and helping to detect early signs of wear. Other offerings include our SIP-valve service, reconditioning and crew training.

Download our catalogue

Get our PDF catalogue sent straight to your inbox for a helpful overview of our products, services and client case studies.

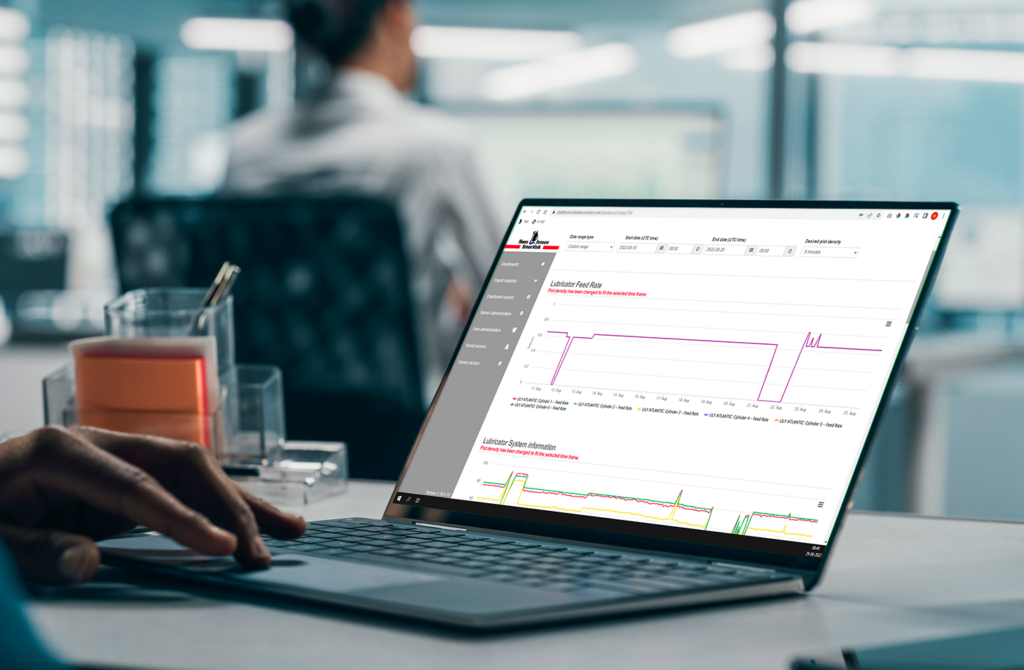

Hans Jensen Smartlink™

Online lubrication portal for performance optimization and remote surveillance.

Product FAQ

There are four main benefits. The cylinder lubrication system distributes a thin and even oil film on the cylinder liner that minimizes wear. The beneficial chemical compounds of the cylinder oil neutralize sulphury acids formed during combustion on piston rings and cylinder liners. The oil also keeps the cylinder free from deposits as well as provide a gas tight seal between the liner and piston rings.

If you implement EPL to comply with EEXI, it most likely means that you reduce the load of the engine. When the load is reduced, the OEM cylinder lubrication systems reduce the injection frequency of the cylinder oil. In other words, the engine will run on ‘old’ oil, during an increased number of dry piston strokes.

Our approach is therefore injection of oil in each piston stroke, which prevents a deteriorated cylinder condition even at reduced loads.

• Reduces operational cost for cylinder lubrication oil by up to 50%

• The cylinder condition is improved using efficient lubrication technology

• Extend the life time of cylinder liners and piston rings (TBO)

• Reduce the work load for engine crew

• Reduce the CO2 and Particulate Matter (PM) emissions

• Prepare for EEXI and the use of greener fuels

Hans Jensen Lubricators is the only company in the world to offer cylinder injection in every piston stroke and atomizing lubrication oil into the combustion chamber.

Contact us

Please fill out the form if you would like to know more about Hans Jensen solutions and your savings potential.

If you are a client, please specify your inquiry below for faster and more specific feedback from our staff.